Are you in the process of setting up a bottling plant and need guidance on choosing the right water filling machine? Look no further! In this comprehensive guide, we will walk you through the factors to consider when selecting a water filling machine for your bottling plant.One of the first things t

Are you looking to optimize your juice production line and achieve maximum efficiency? In today's competitive market, every business strives to improve productivity while reducing costs. This article will provide you with valuable insights on how to optimize your juice production line for maximum ef

Maintaining the performance and efficiency of a carbonated beverage filling machine is crucial for any beverage manufacturing company. Regular maintenance not only ensures consistent product quality but also extends the lifespan of the machine, saving both time and money in the long run. In this art

Water filling lines play a crucial role in the efficient functioning of bottling plants. With the increasing demand for bottled water, it has become imperative for bottling plant owners to invest in reliable and high-quality water filling lines. In this article, we will explore the various benefits

In today's fast-paced and competitive market, businesses are constantly seeking ways to enhance their operations and gain a competitive edge. One such solution that has proven to be highly beneficial is the implementation of a fully automated water filling line. This article explores the advantages

CGF16-16-5

ALPS

8422301090

| Availability: | |

|---|---|

| Quantity: | |

This machine is mainly used in the water filling operations. The three functions of bottle rinsing, filling and capping are composed in one body of the machine. The machine is used in filling mineral water and purified water in bottles made of polyester and plastics. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles. The advanced Mitsubishi programmed controller (PLC) is adopted to control of the machine to run automatically while a transducer is used in the bottle-entering chains to adjust speed and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably. The aluminum theft proof cap and plastic cap can be adopted. The machine is an idea-preferred equipment for beverage manufacturers.

| Name: Washing filling and capping 3 in 1 machine | |

| Model | CGF16-16-5 |

Number of washing heads | 16 |

Number of filling nozzles | 16 |

Number of capping heads | 5 |

Capacity at 500ml bottle size | 6000-8000 bottles/hour |

Application bottle & cap | PET bottle & Screw cap |

Suitable bottle height | 160-320mm |

Suitable bottle diameter | ¢50-¢115 |

Power of main motor | 3.8KW |

Water pressure | >0.06MPa≤0.2Mpa |

Filling type | Gravity filling |

Filling temperature | Room temperature |

Dimension(mm) | 2400*1880*2300mm |

Weight(kg) | 3200kg |

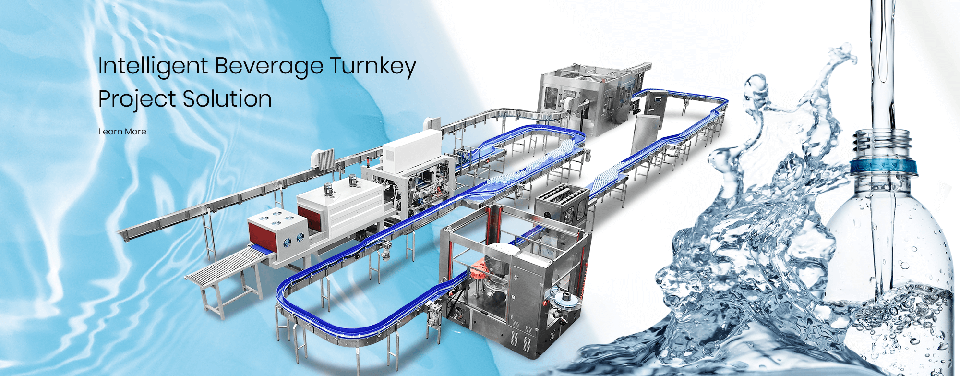

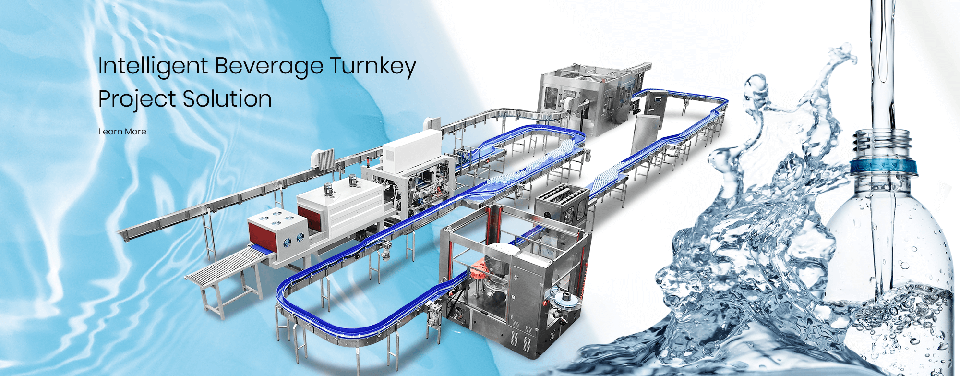

We supply complete solution for the water bottling plant, including water treatment plant, PET bottle blowing machine, washing filling capping machine, code printer, labeling machine, shrink wrapping machine and so on.

According to customer's raw water analysis report and the final water standard request, we will suggest customer to choose the suitable water treatment plant.

Bottle blowing machine is to make plastic bottles for mineral water, carbonated drink, juice and so on. It is widely used in the food and beverage package industry.

| Technical Parameters | ||||||

| Model | CGF8-8-3 | CGF14-12-5 | CGF16-16-5 | CGF24-24-8 | CGF32-32-8 | CGF40-40-10 |

| Max Capacity | 3000bph | 4500bph | 7000bph | 12000bph | 15000bph | 18000bph |

| Bottle Material | PET Bottle | |||||

| Bottle Diameter | φ50—φ116mm | |||||

| Bottle Height | 160-320mm | |||||

| Air Pressure | 0.2-0.8Mpa | |||||

| Washing Pressure | >0.06MPa, ≤0.2MPa | |||||

| Rated Power | 3.8KW | 4.5KW | 4.8KW | 5.5KW | 7.5KW | 8.5KW |

| Overall Size | 2200*1600 *2200mm | 2400*1880 *2300mm | 2800*2200 *2300mm | 3050*2400 *2300mm | 3800*2600 *2500mm | 4000*3150 *2500mm |

| Weight | 2800kgs | 3200kgs | 4200kgs | 5500kgs | 6500kgs | 7500kgs |

There are mainly three kinds labeling machine, PVC sleeve shrink labeling machine, pressure sensitive sticker labeling machine and OPP hot glue labeling machine.

There are mainly two kinds of case packing machine, film shrink wrapping machine and carton packing machine. For film shrink wrapping machine, there is also with for unprinted film and for printed film, then there is also shrink film with carton tray. For carton packing machine, there is tape sealing type and hot glue sealing type.

We design the factory layout based on customer factory sizes, whole line design is based on famous brand motors and automatic lubricant system, with less power consumption and space.

Q: Can your company provide turnkey project from A to Z?

This machine is mainly used in the water filling operations. The three functions of bottle rinsing, filling and capping are composed in one body of the machine. The machine is used in filling mineral water and purified water in bottles made of polyester and plastics. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles. The advanced Mitsubishi programmed controller (PLC) is adopted to control of the machine to run automatically while a transducer is used in the bottle-entering chains to adjust speed and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably. The aluminum theft proof cap and plastic cap can be adopted. The machine is an idea-preferred equipment for beverage manufacturers.

| Name: Washing filling and capping 3 in 1 machine | |

| Model | CGF16-16-5 |

Number of washing heads | 16 |

Number of filling nozzles | 16 |

Number of capping heads | 5 |

Capacity at 500ml bottle size | 6000-8000 bottles/hour |

Application bottle & cap | PET bottle & Screw cap |

Suitable bottle height | 160-320mm |

Suitable bottle diameter | ¢50-¢115 |

Power of main motor | 3.8KW |

Water pressure | >0.06MPa≤0.2Mpa |

Filling type | Gravity filling |

Filling temperature | Room temperature |

Dimension(mm) | 2400*1880*2300mm |

Weight(kg) | 3200kg |

We supply complete solution for the water bottling plant, including water treatment plant, PET bottle blowing machine, washing filling capping machine, code printer, labeling machine, shrink wrapping machine and so on.

According to customer's raw water analysis report and the final water standard request, we will suggest customer to choose the suitable water treatment plant.

Bottle blowing machine is to make plastic bottles for mineral water, carbonated drink, juice and so on. It is widely used in the food and beverage package industry.

| Technical Parameters | ||||||

| Model | CGF8-8-3 | CGF14-12-5 | CGF16-16-5 | CGF24-24-8 | CGF32-32-8 | CGF40-40-10 |

| Max Capacity | 3000bph | 4500bph | 7000bph | 12000bph | 15000bph | 18000bph |

| Bottle Material | PET Bottle | |||||

| Bottle Diameter | φ50—φ116mm | |||||

| Bottle Height | 160-320mm | |||||

| Air Pressure | 0.2-0.8Mpa | |||||

| Washing Pressure | >0.06MPa, ≤0.2MPa | |||||

| Rated Power | 3.8KW | 4.5KW | 4.8KW | 5.5KW | 7.5KW | 8.5KW |

| Overall Size | 2200*1600 *2200mm | 2400*1880 *2300mm | 2800*2200 *2300mm | 3050*2400 *2300mm | 3800*2600 *2500mm | 4000*3150 *2500mm |

| Weight | 2800kgs | 3200kgs | 4200kgs | 5500kgs | 6500kgs | 7500kgs |

There are mainly three kinds labeling machine, PVC sleeve shrink labeling machine, pressure sensitive sticker labeling machine and OPP hot glue labeling machine.

There are mainly two kinds of case packing machine, film shrink wrapping machine and carton packing machine. For film shrink wrapping machine, there is also with for unprinted film and for printed film, then there is also shrink film with carton tray. For carton packing machine, there is tape sealing type and hot glue sealing type.

We design the factory layout based on customer factory sizes, whole line design is based on famous brand motors and automatic lubricant system, with less power consumption and space.

Q: Can your company provide turnkey project from A to Z?